Complete monitoring of machines in company Kovolis Hedvikov - Czech Republic

Reference

- Country: Czech Republic

- Name: Complete monitoring of machines in company Kovolis Hedvikov

- Implemenmted by: Kybertec s.r.o.

- Date: 2014

- Control system: Tecomat Foxtrot

- Software: Mosaic, SCADA Reliance

Company Kovolis Hedvikov located in Tremosnice is the biggest press foundry in Czech and Skovak Republic with 6 thousands tons of aluminium per year.

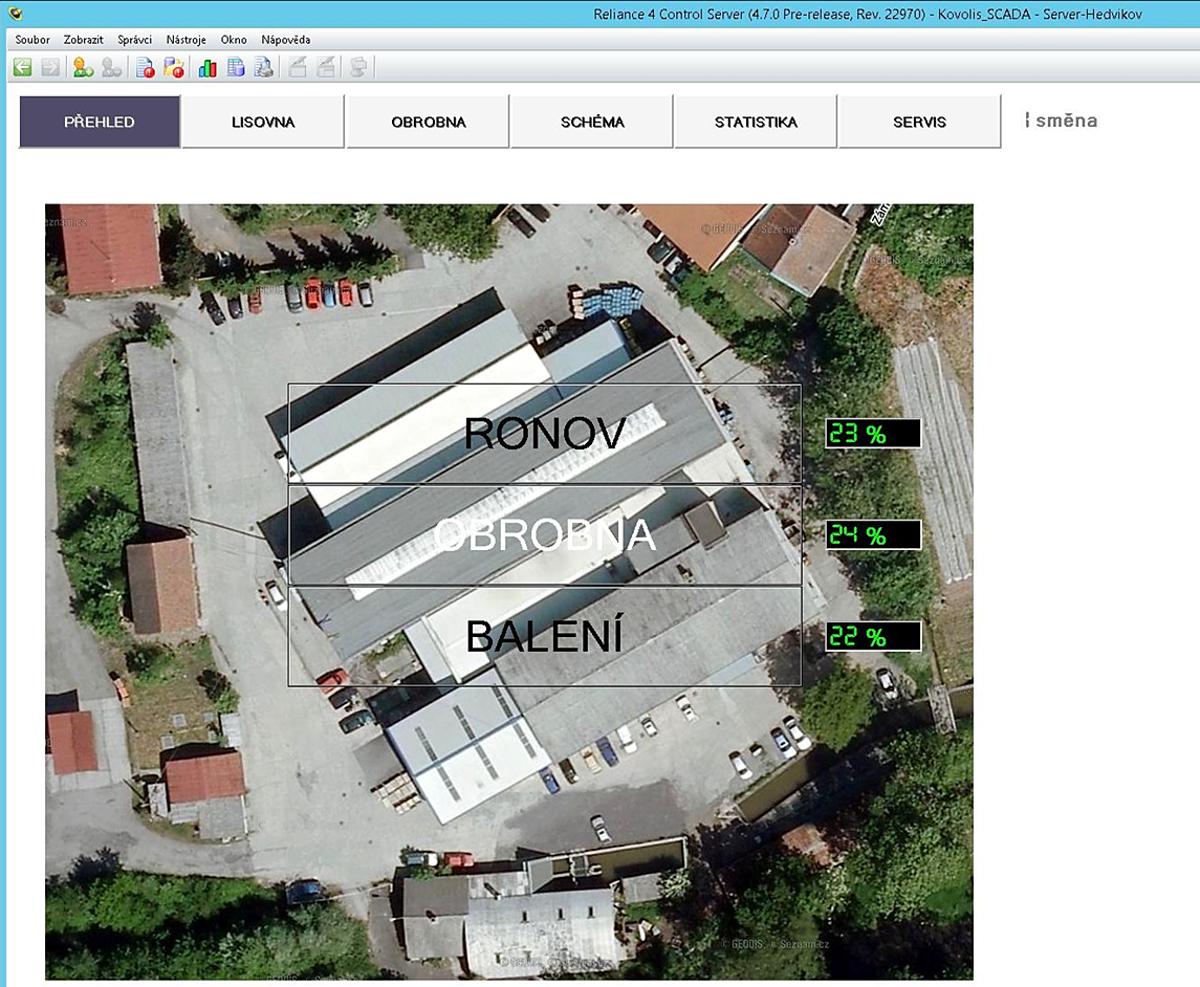

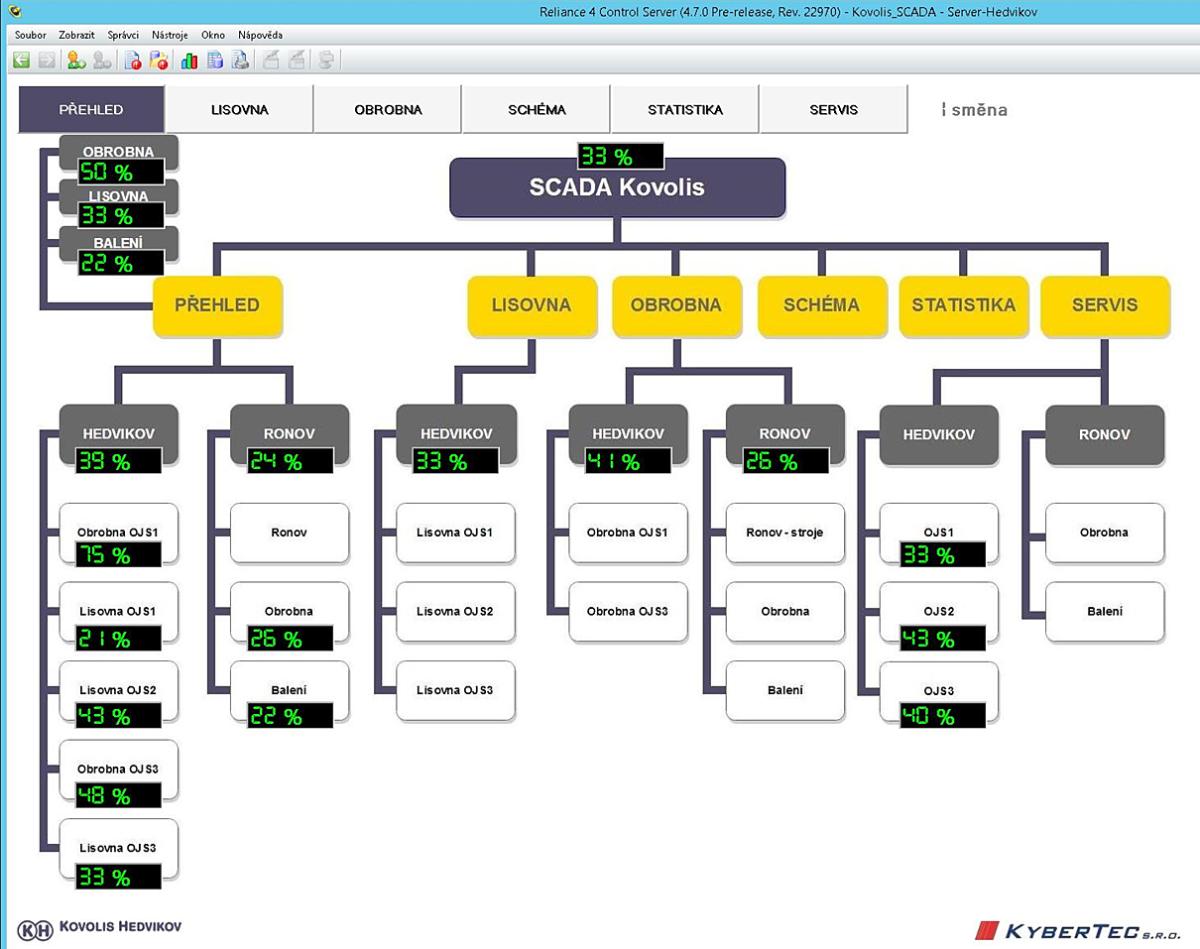

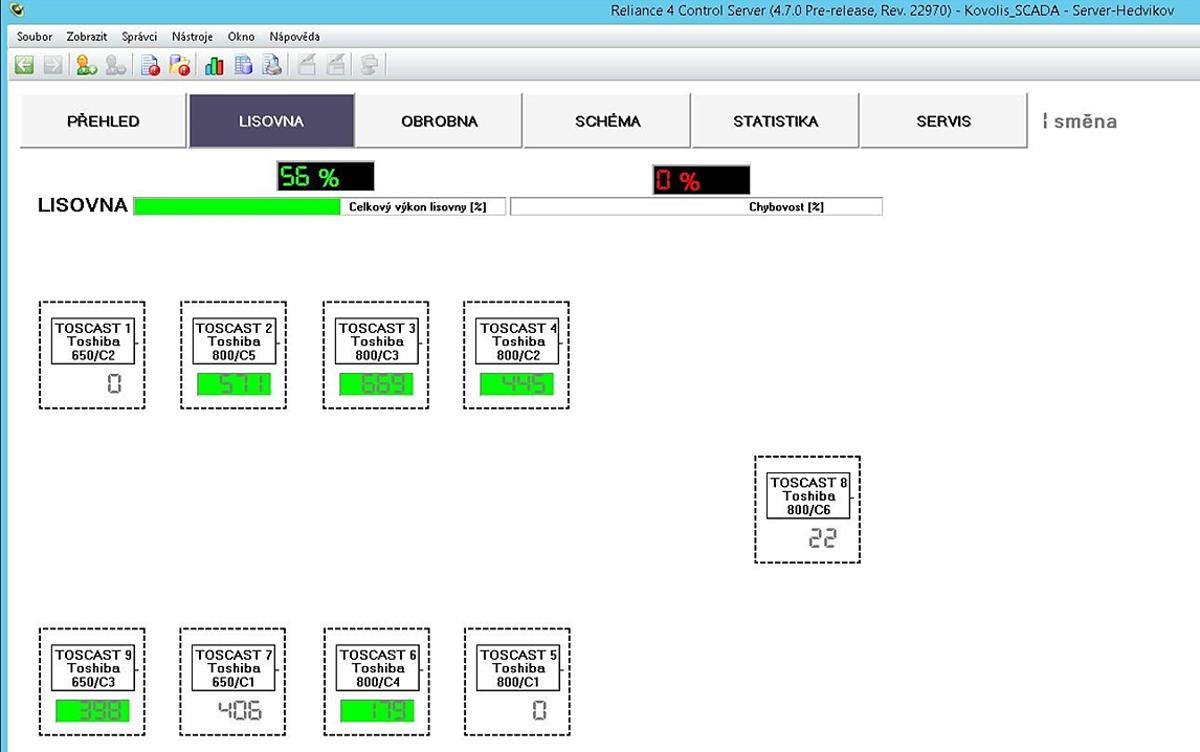

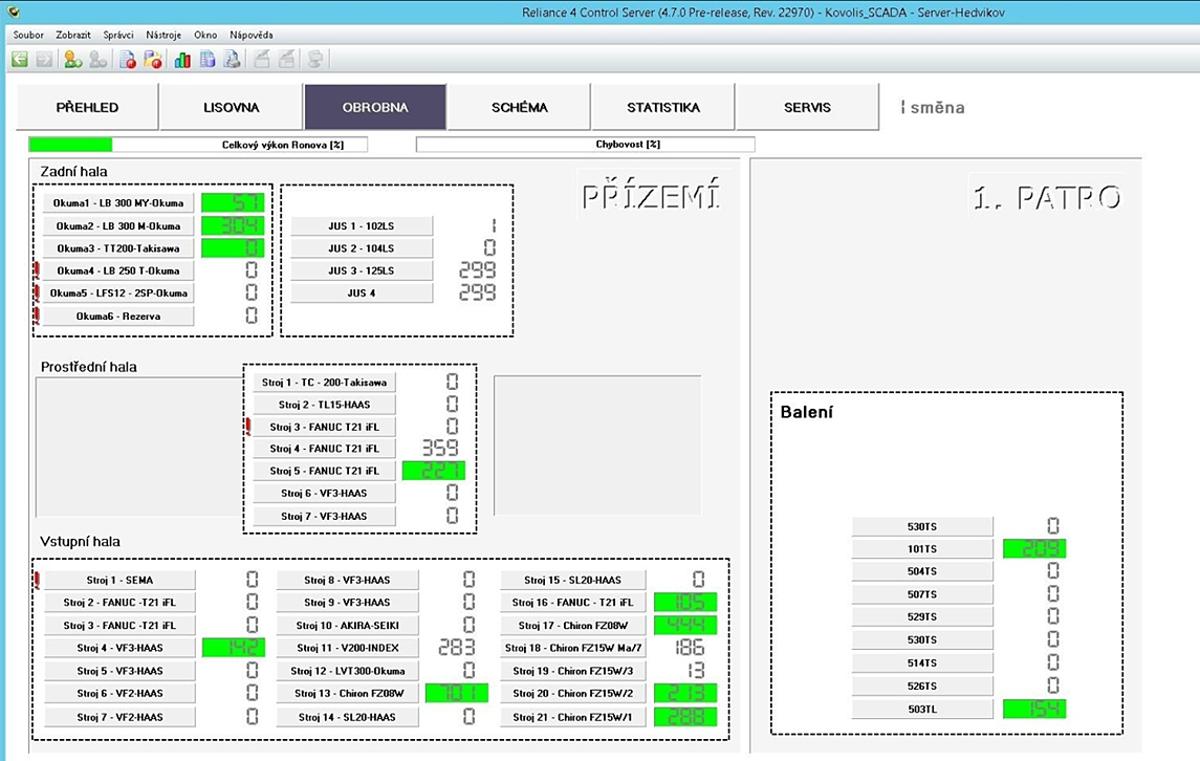

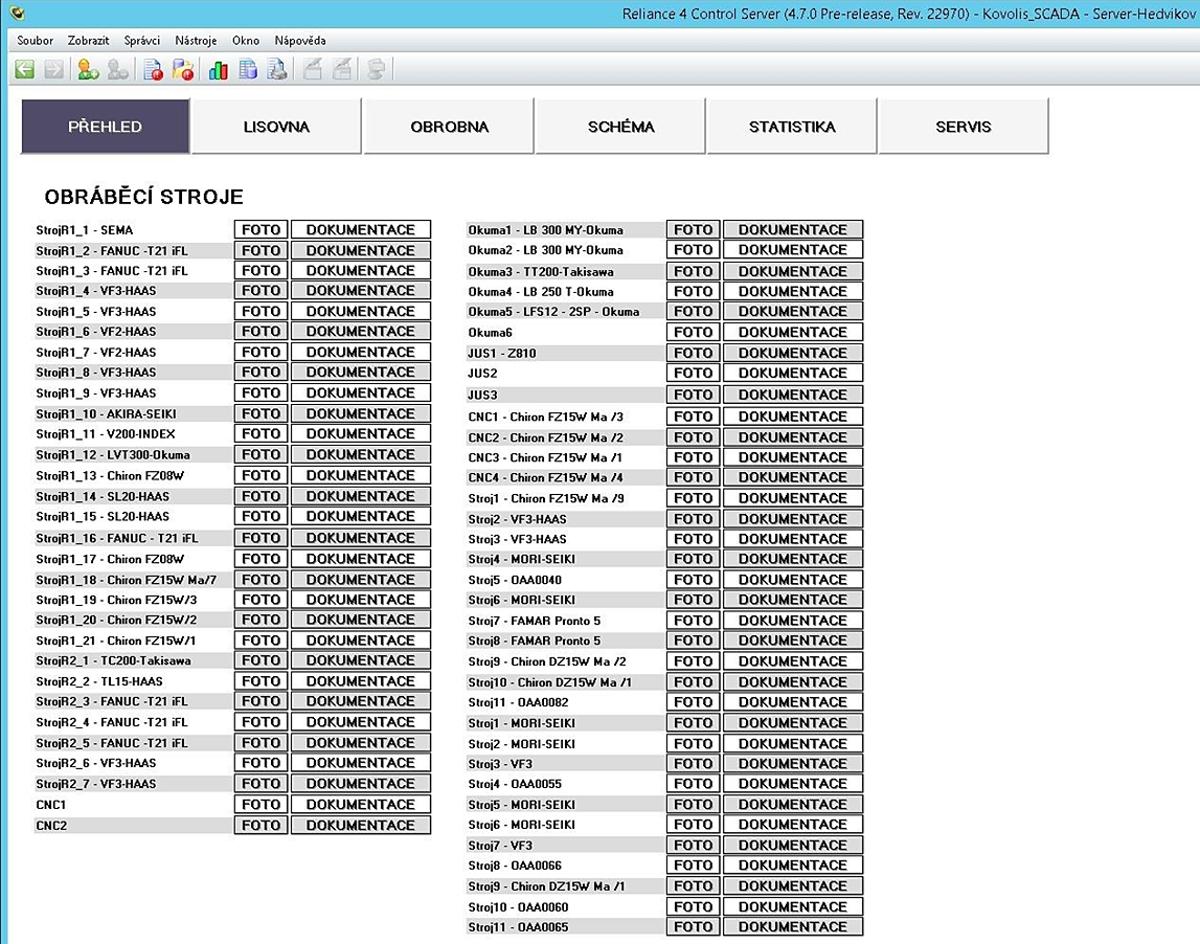

During 2014, our customer - company Kybertec implemented a complete system for monitoring of machines for company Kovolis Herlikov (Czech Republic). Monitoring system has been implemented in plant in Hedvikov and Ronov nad Doubravou. There are monitored manufacturing parametres of more than one hundred machines. Machines are divided to machining machines, press machines and checking machines.

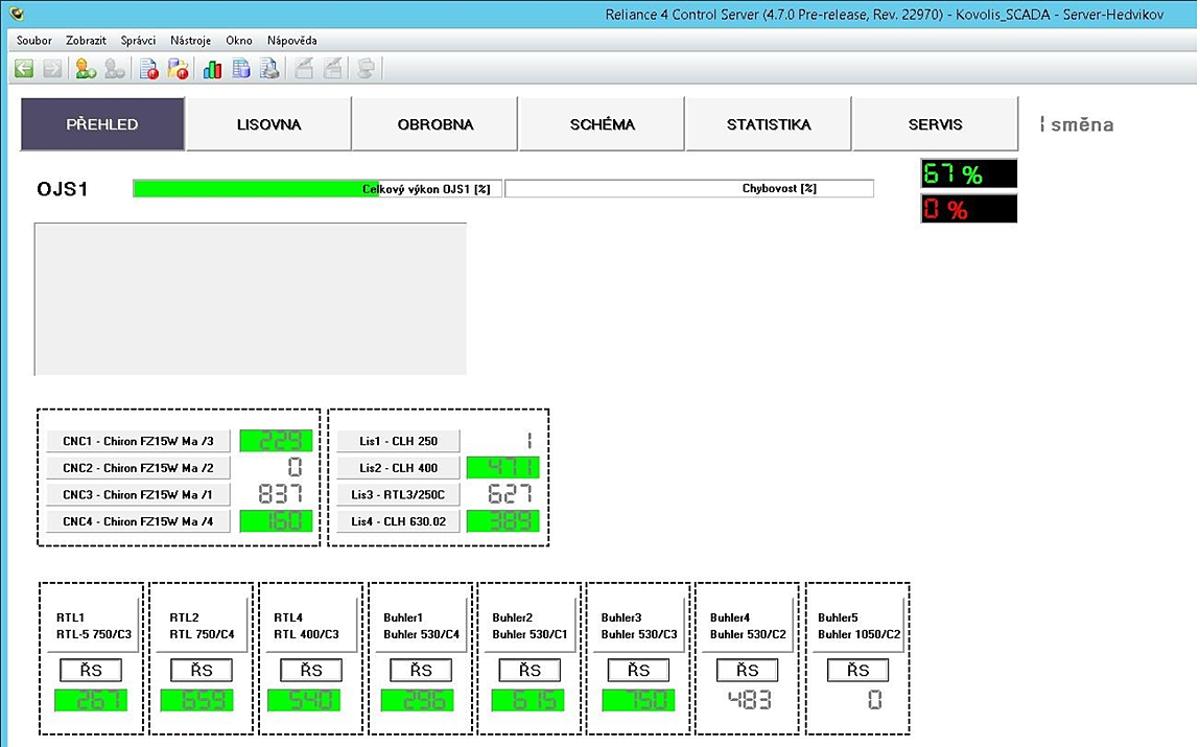

For monitoring system, there has been projected distributed system with tens of PAC Tecomat Foxtrot modules. Data are read via IO and serial channels. In case of press machines monitoring we can say that this is an unique solution that never been used in the Czech Republic.

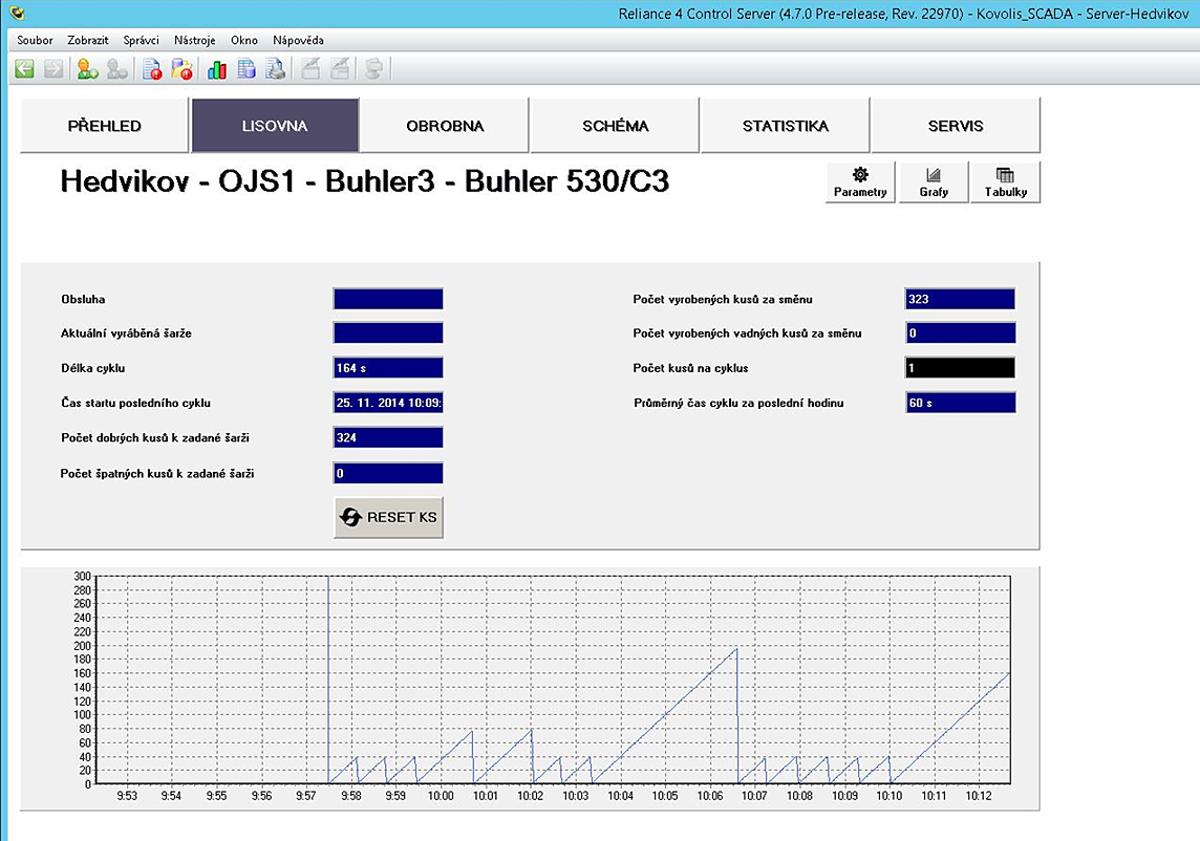

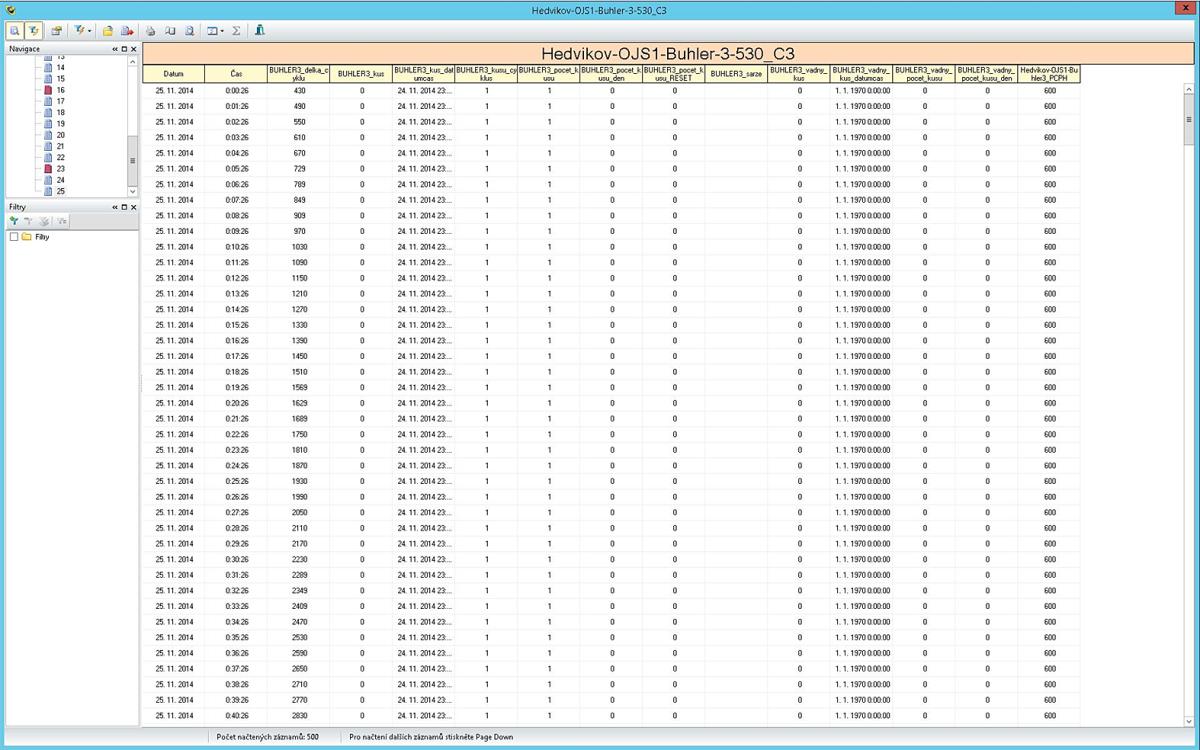

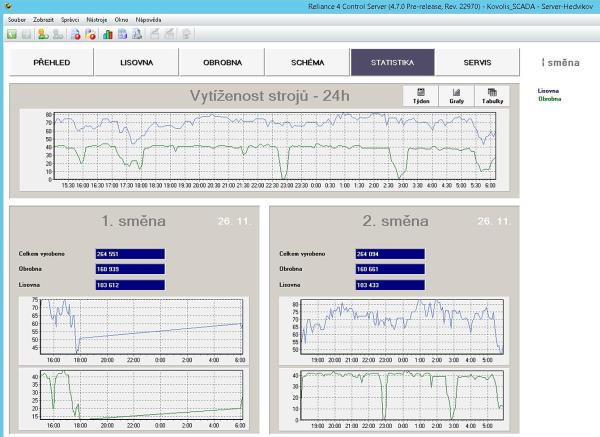

Processed data are provided to superordinate SCADA system Reliance vesion 4.7.0, which is going on the processing. For each monitored machine there are available databases, graphs and other parameters, for instance for maintenance. Via scripted tool there are created statistics, which show global overview of real productivity and performance of all machines according to shifts and days.

For working with SCADA system there is a key point - Web interface of system Reliance, where are used both web clients and Smart clients. Together with implementation of monitoring system there was created a standardized workplace of operation for machines with heavy-duty PC and client Reliance and processing data from access system.

SCADA system is also connected with implemented MES system (exchange of the data via MS SQL server), which is dedicated for a complex control of manufacturing. Among these two systems is running exchange of information of manufacturing series, present operators and other important information.

System was created as open one and ready for future expansion. It means that both hardware and software of the system are ready for easy expansion.