Silicon plates washing process control - Finland

Reference

Implementation: ALL4FAB s. r. o.

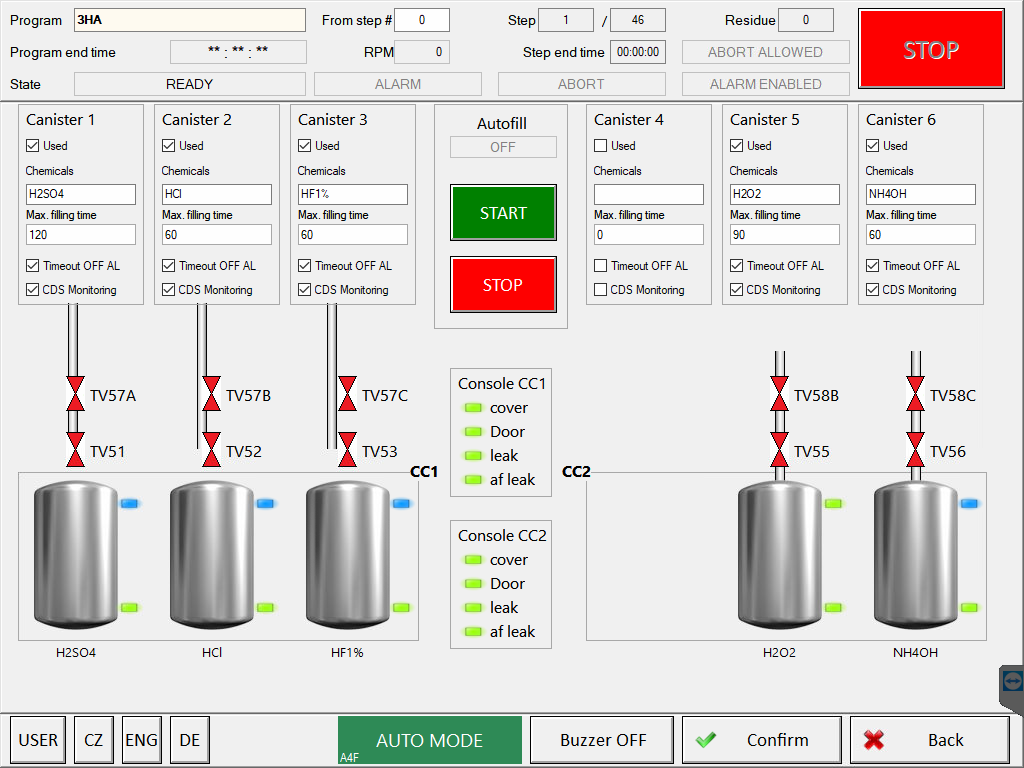

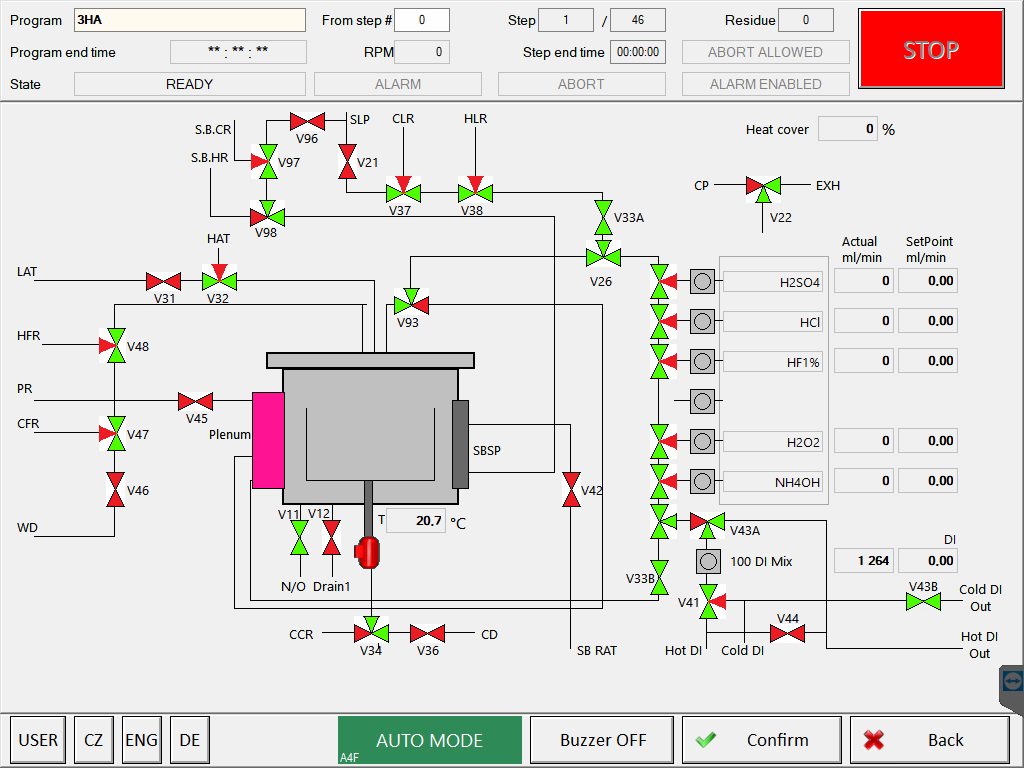

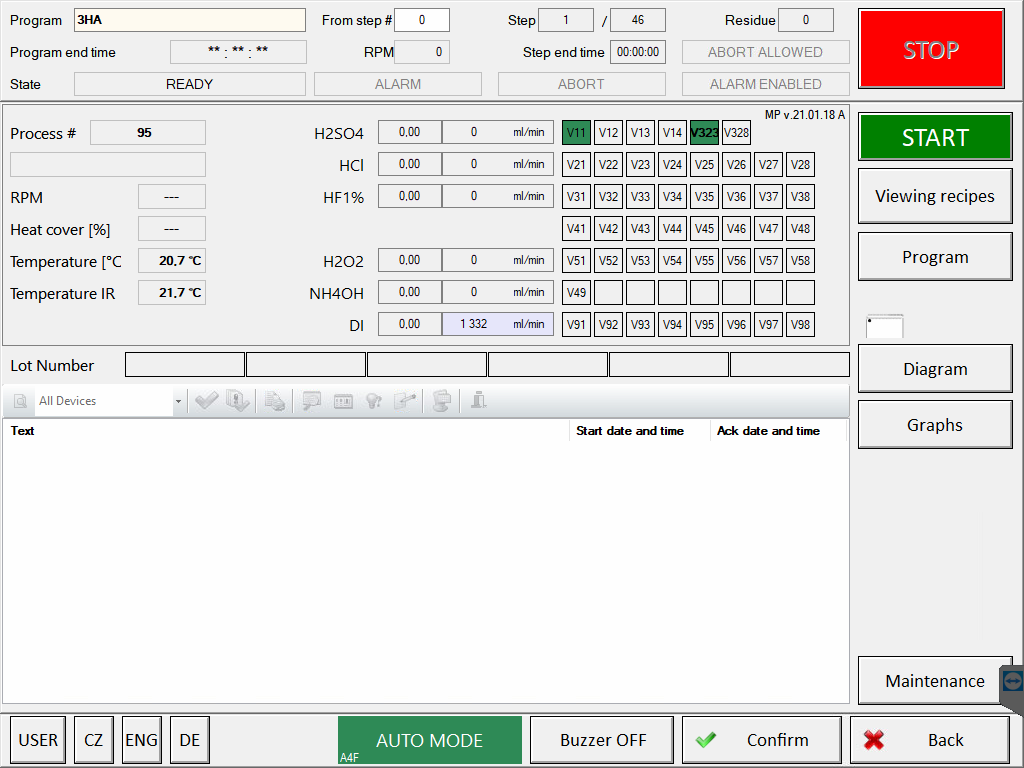

The Finnish company Okmetic is a manufacturer of silicon plates for the semiconductor industry. The company ALL4FAB supplied her with technological equipment for washing and etching these plates. The machine itself is a special washer for washing, etching and drying silicon wafers in very high purity. The basis of the entire device is the Teco TC700 PLC control system and an industrial computer working as a visualization with the Reliance SCADA/HMI system.

The task of the device is to remove molecular remains of organic impurities from the surface of silicon plates, a very thin layer of natural oxide that forms on the surface of the plates with a thickness of the order of nanometers, and also to remove possible metallic contamination from the plates, such as iron, which in a concentration of 1 atom of iron per 100,000 silicon atoms can cause irreversible crystallographic deformations of silicon during subsequent high-temperature operations.

The process itself takes place in a hermetically sealed, aspirated, chemically resistant chamber, where washing is carried out in demineralized water at room temperature or hot demineralized water at a temperature of 75 °C according to the selected recipe. The chemical cleaning itself is then carried out with chemicals that are mixed in the exact ratio during the process according to the selected program and are subsequently atomized into a very fine aerosol that is applied to the surface of the silicon plates.

It is mainly a combination of H2SO4+H202, then diluted hydrofluoric acid HF to the required concentration, the next steps are then a mix of chemicals H2O2+NH4OH diluted in the exact ratio with demineralized water and HCl+H2O2 again precisely diluted with demineralized water. Between individual applications of chemicals always wash silicon substrates in demineralized water, again according to the selected recipe.

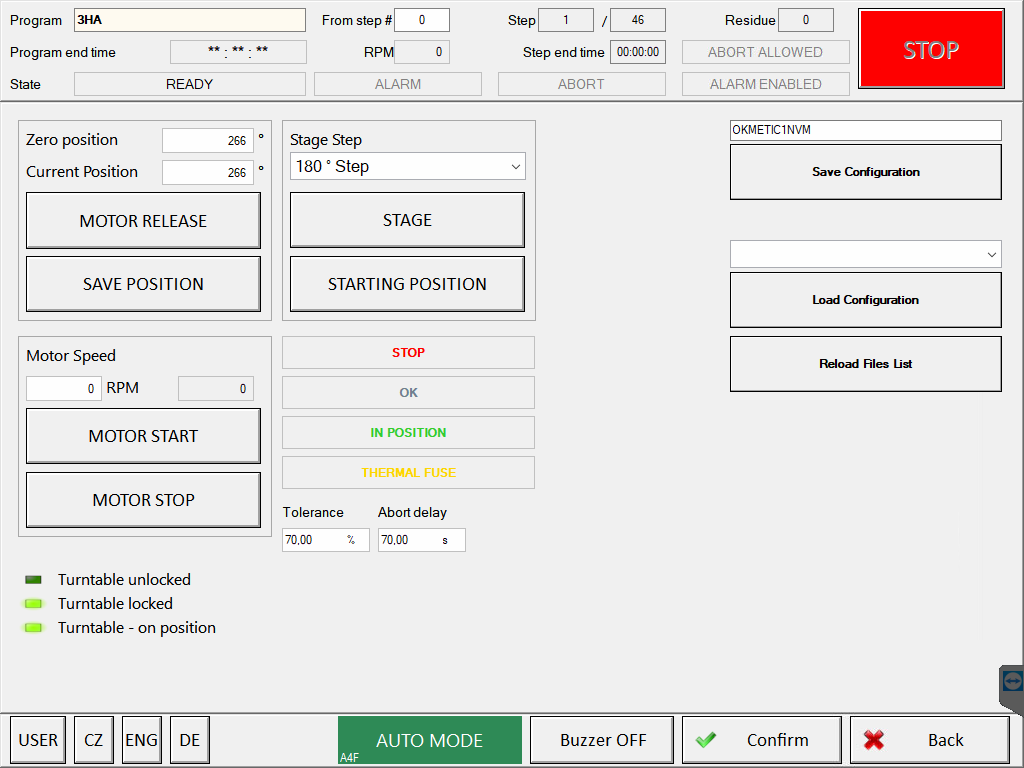

These chemicals, rinsing water after the chemicals and nitrogen for drying the plates are applied through a special sprayer (atomizer), which is placed statically in the center of the working chamber and around it rotates a carousel with reservoirs in which the silicon wafers are placed. The rotation and position of the carousel is again controlled by the TC700 via the RTU Modbus interface, which communicates with the servo amplifier driving the motor. The entire system also communicates with central large chemical reservoirs that automatically replenish chemicals into the reservoirs of the facility itself.

For this purpose, ALL4FAB supplied a special dishwasher for these very clean technologies. The basis of the entire device is the Teco TC700 PLC control system and an industrial computer working as a visualization with the Reliance SCADA/HMI system.

Basic PLC specifications:

- 96 x digital outputs

- 96 x digital inputs

- 16 x analog inputs

- 8 x analog outputs

- 1 x RS485 Modbus communication with temperature controllers

- 1 x RS485 Modbus communication for remote control of peripheral devices for automatic chemical replenishment

- 1 x RS232 Communication with the demineralized water flow heater

- 1 x RS232/485 For further expansion

- 1 x Ethernet for SCADA/HMI communication

- 1 x Ethernet for communication with the motor servo system

The visualization is displayed on an industrial PC with a 15" touch screen, SW Reliance Control / Server 3000 points. As an additional device, the company ALL4FAB also supplied a flow heater of demineralized water, which is controlled by a Foxtrot PLC.

Visualization enables monitoring and control of the entire technology, especially:

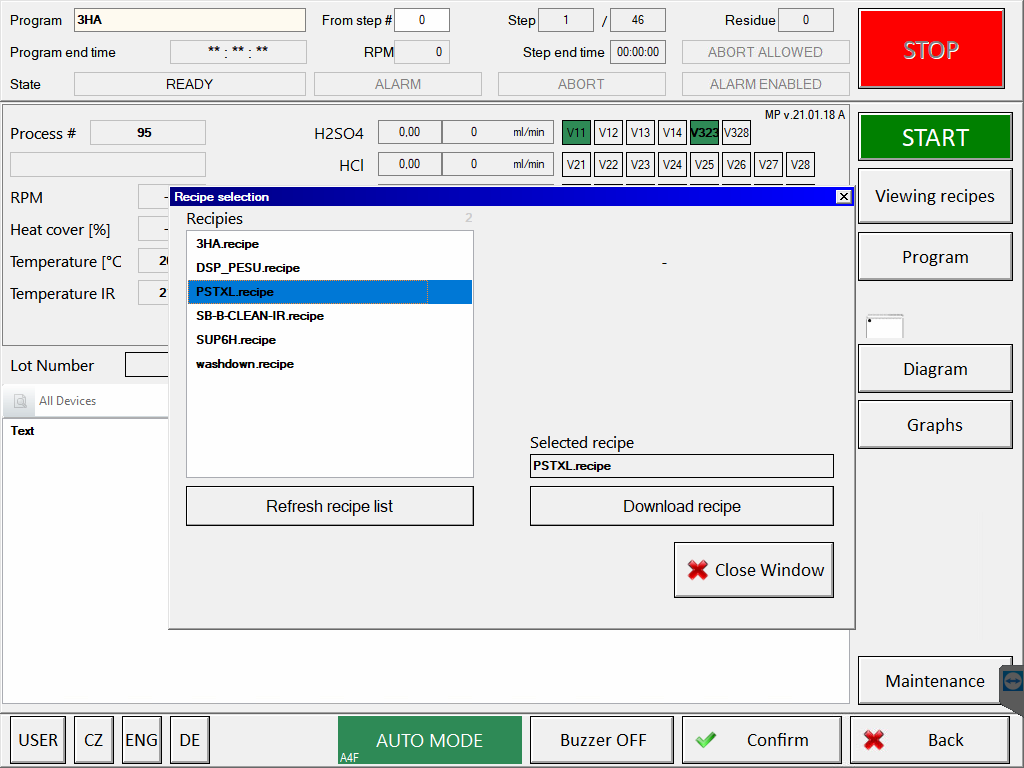

- Selecting a program recipe

- Archiving of technological parameters (flow rates, pressures, temperatures)

- Monitoring device alarms and aborts

- Visualization of the entire technological proces

- Editor for creating and editing recipes

- Definition of user inputs / outputs

- Option to connect to production control using OPC UA server (optional)

Basic information about ALL4FAB:

ALL4FAB s.r.o. is a young, dynamically developing company operating in the field of automation, chemical processes in semiconductor technologies, engineering, research laboratories and other sectors of hit technologies and Industry 4.0. It offers individual solutions in close cooperation with the customer and with long-term experience in the field of the semiconductor industry, the electrical engineering industry, control systems for demanding industrial applications and participation in research and development activities, we are a partner who will design a turnkey solution for your needs.

Company offer:

- production of single-purpose machines

- automation of existing technologies

- modernization of existing technologies

- comprehensive supply of control systems for controlling technological units, machines, production lines, including software and visualization

- supply of switchboards with control systems and MaR systems

- research and development of technological and chemical processes, cooperation in research and development.